M2M Personalization Machine

· Realize the functions of personalized IC writing, laser marking and packaging conversion of M2M chips.

· Adopt reversing station positioning mode.

· 6 sets of independently driven handling arms, easy maintenance, equipped with visual positioning components.

· High production capacity: When the IC writing time is less than 29S, the production capacity can reach 4500UPH.

· Applicable to trays and rolls.

· Applicable packages: QFN, SOP, etc.

- Information

Product Introduction

Introduction of M2M Chip Personalization Machine

Ulian's M2M-4500 chip personalized data writer has been developed through years of technology and software, and can be used for the personalization of various specifications of chip production. The equipment is easy to operate and maintain, and has high output quality.

The M2M chip personalized data writer can perform chip electrical performance testing, chip personalized data writing, and surface laser personalized printing on M2M chips in QFN, DFN, VSOP8 and other packaging forms, automotive electronics SE (Security Element-security chips), eSIM and other smart devices.

M2M-4500 can provide high-speed, stable, and safe personalized production services for global mobile operators, smart device OEMs, and automotive electronic security chip manufacturers.

Main Functions of Equipment Production Processing Module

Material delivery unit:

Automatic tray feeding: automatic tray loading/unloading, tray storage capacity (20/20 trays)

Electric double feeder feeding;

Optional support for vibration feeder feeding, support for tube feeding

Optional support for feeding chip detection

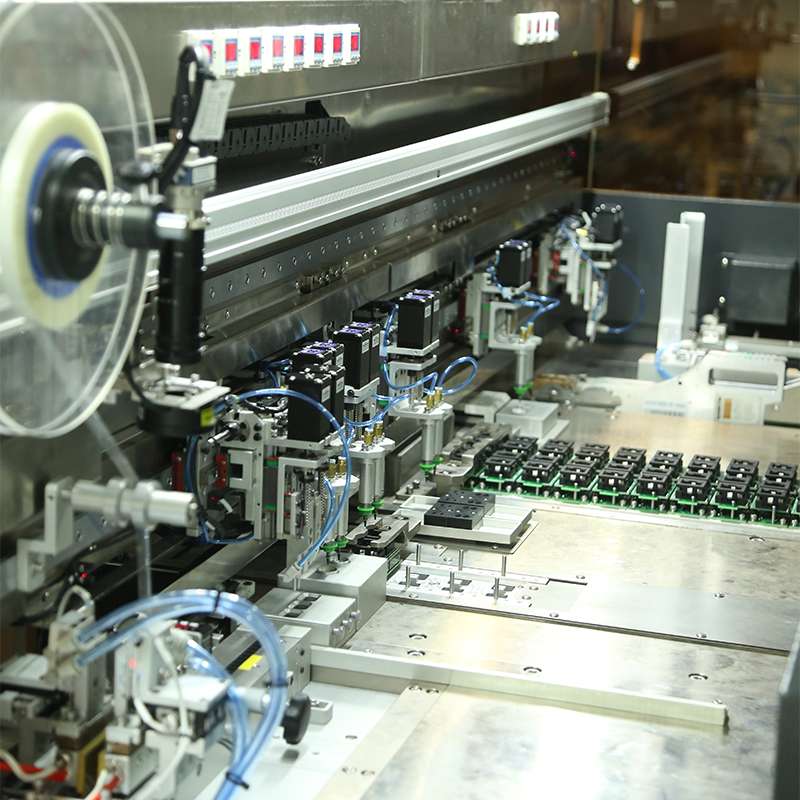

Handling unit:

Servo-driven transport arms, driven separately.

Z-axis nozzles are independently controlled and vacuum gripped.

Input and output transport arms adopt variable-pitch structure.

Chip dual suction and dual release.

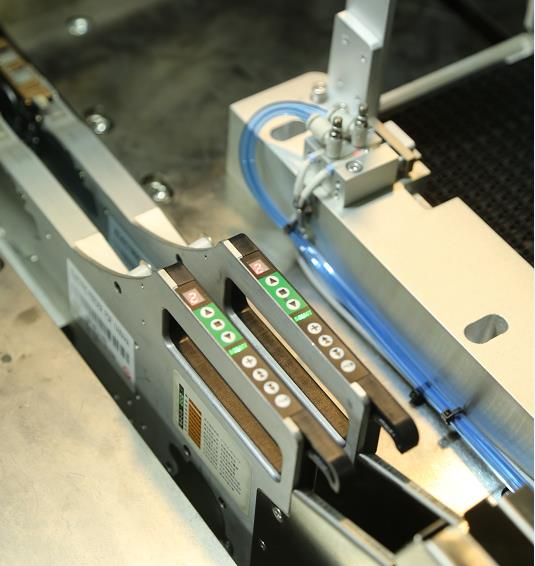

IC writing unit:

Dedicated IC base plate, pin hole positioning.

The system can write 40 ICs at the same time to eliminate or shorten the system waiting time generated when burning high-capacity memory IC chips.

Supports online installation of multiple varieties.

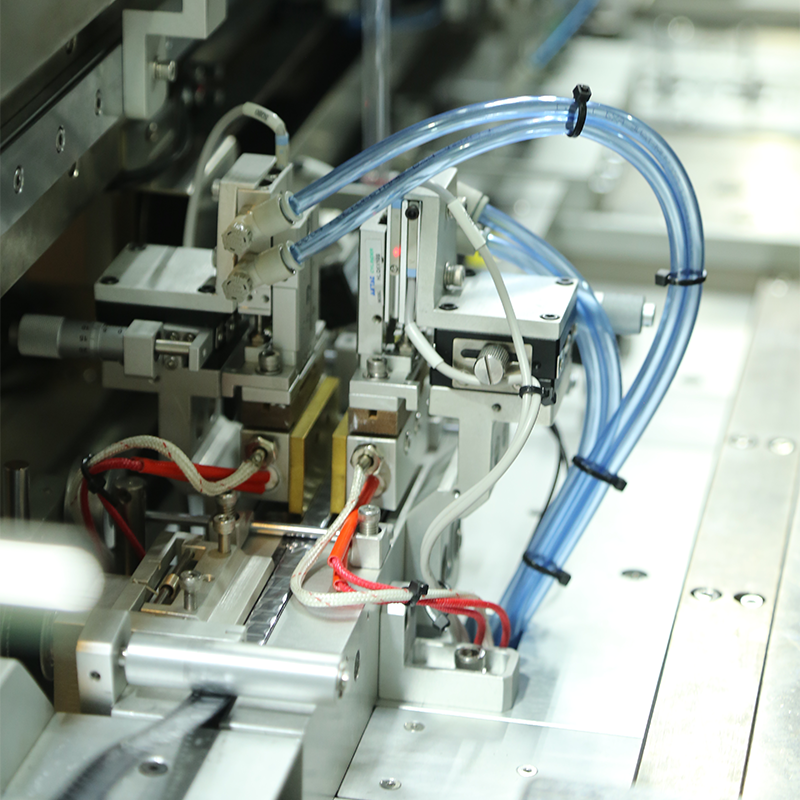

Laser marking unit:

Adopt reciprocating material conveying, 4 positions;

Motion mechanism: servo drive;

The previous station sends marking data to the laser server.

If writing fails, the card will not be printed.

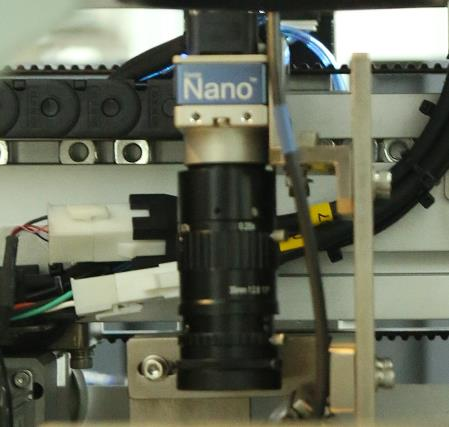

OCR verification unit:

Used to detect laser marking effects.

Can recognize barcodes, Arabic numerals, English letters, Chinese characters, etc.

Receiving unit:

Roll discharging: heat-sealed & self-adhesive, width 8 ~ 20mm.

Tray discharging: manual tray change.

Carrier single-drive double-wheel structure, stable carrier drive, accurate positioning.

Fast switching of carrier types;

Automatic centering of carrier.

Counting function after heat sealing.

Capacity Table

Personalized Time and Capacity Curves:

| Card writing time | 29 | 32 | 39 | 47 | 54 | 66 |

| Yield | 4500 | 4270 | 3500 | 2900 | 2500 | 2050 |

Laser Printing Time and Capacity Curve:

| Laser Printing Time | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 |

| Yield | 4500 | 3500 | 3000 | 2450 | 2000 | 1700 |

Parameter Table

| Specifications | |

| Body size: | 2000×1250×1600mm(L×W×H) |

| Weight: | 700KG |

| Power Supply: |

|

| Gas source: |

|

| Laser precision: | ±0.2mm |